Design Support

Vibration measurement system using Raspberry Pi products

Overview

This article introduces a measurement system that connects an acceleration sensor and vibration sensor to a Raspberry Pi, outputting the measured data to a Micro SD card. Using a Raspberry Pi allows for the creation of a compact and power-efficient measurement system, suitable for various measurement targets and locations.

Additionally, a measurement system (see below: Configuration example 2) that connects to a waterproof and dustproof acceleration sensor and vibration sensor can be set up, making it adaptable to specific environments.

Click here for an example of use in Mt. Aso, the world's largest caldera

This measurement system is compatible with Raspberry Pi 4B. It does not support Raspberry Pi 5.

■System configuration example

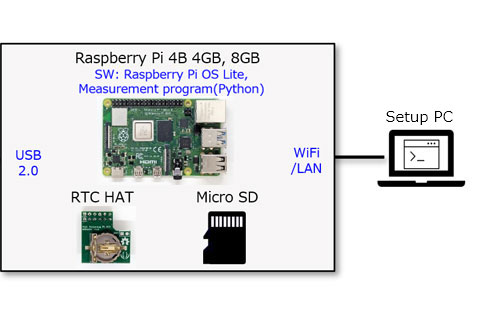

Configuration example 1 (using built-in type sensor)

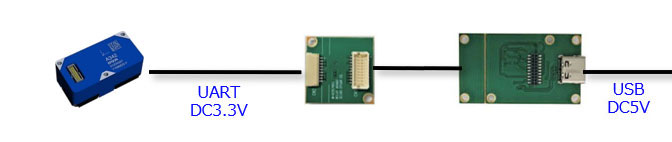

| Acceleration sensor: M-A352AD10 Vibration Sensor: M-A342VD10 |

Relay Board M-G32EV051 |

Evaluation Board |

|

|

|||

| |

|||

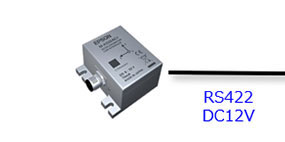

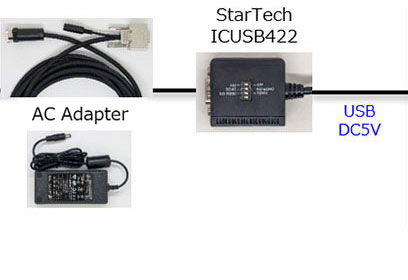

Configuration example 2 (using waterproof and dustproof sensor)

| Acceleration sensor: M-A552AR10 Vibration Sensor: M-A542VR10 |

RS422 Communication Cable: KD-002-XXX |

|

|

|

|

| |

||

■When measuring with multiple sensors

Operation has been confirmed under the following measurement conditions.

| Sensor used (built-in type) |

Number of sensors | Sampling rate | USB-C conversion board | USB Hub |

|---|---|---|---|---|

| Vibration Sensor: M-A342VD10 |

4units | 3000sps | Evaluation board: M-G32EV041 |

ELECOM U2H-SN4NB |

| Acceleration sensor: M-A352AD10 |

4units | 1000sps |

| Sensor used (waterproof and dustproof type) |

Number of sensors | Sampling rate | How to connect | RS422-USB conversion hub |

|---|---|---|---|---|

| Vibration Sensor: M-A542VR10 |

4units | 3000sps | Guide to Connecting Waterproof/Dustproof Sensor(s) to Host(s) | StarTech ICUSB234854 |

| Acceleration sensor: M-A552AR10 |

4units | 1000sps |

■Documentation

| Document | Explanation |

|---|---|

| Setup Manual for Vibration Measurement System using Raspberry Pi Products |

This is a manual for constructing this measurement system. |

| Operation Manual for Vibration Measurement System using Raspberry Pi Products |

This is a manual for using the measurement system that you have constructed. |

■Program

| Document | Explanation |

|---|---|

| Measurement sample code (Python) (ZIP, 89KB) | This is sample code for a measurement program to be installed on Raspberry Pi. *By using this sample code, you agree to the license stated in the source file. *This sample code is compatible with Raspberry Pi 4B. It is not compatible with Raspberry Pi 5. |

■Example of use at Mt. Aso

This system was used for long-term earthquake measurement in the volcanic region of Mt. Aso, Kyushu Island, Japan. The system was constructed based on system configuration example 1, and the sensor part was placed in a case and buried underground for measurement. Measurements were successfully completed over two weeks while installed outdoors.

For more details, please see the case study file "We tried Seismic Vibration Measurements/Analysis in the World's Largest Caldera, Mt. Aso!"

Preparation for measurement

The sensor part was buried in the ground and the Raspberry Pi was covered to protect it from direct sunlight.

*To prevent the Raspberry Pi from overheating, place it out of direct sunlight and consider using a heat sink or fan.

| Case File | Explanation |

|---|---|

| We tried Seismic Vibration Measurements in the World's Largest Caldera, Mt. Aso! (Measurement data csv file included) |

This article introduces a measurement example using this system (Configuration Example 1) in the volcanic region of Mt. Aso, Kyushu Island, Japan. |

| We tried Seismic Vibration Analysis in the World's Largest Caldera, Mt. Aso! | This article introduces the analysis of the earthquake vibration data obtained from the above measurements. |

These articles are based on the following technical papers:

- Title: "Quartz Enhanced Micro Electromechanical Systems Accelerometer for Seismic Monitoring: Field Performance in Volcanic Region."

- Publication: IEEE SENSORS JOURNAL

*This paper is co-authored by Tsuji Laboratory at the University of Tokyo and Seiko Epson, with Dr. R. D. Andajani as the first author.